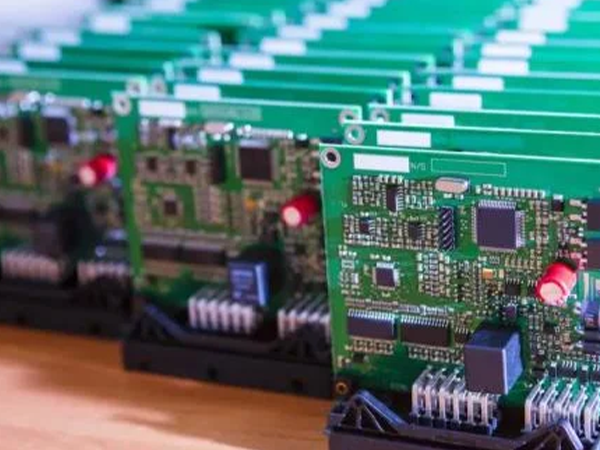

With over 150 years of combined industry experience in Indianapolis PCBA Manufacturing design, fabrication, and assembly, our team is uniquely equipped to meet all PCBA prototype to production needs.

At DIVSYS, we’re transforming the way companies innovate and bring new products to market. Our state-of-the-art equipment, industry-leading speed, and precision—combined with complete start-to-finish transparency—empower customers to accelerate their product development cycle with confidence.

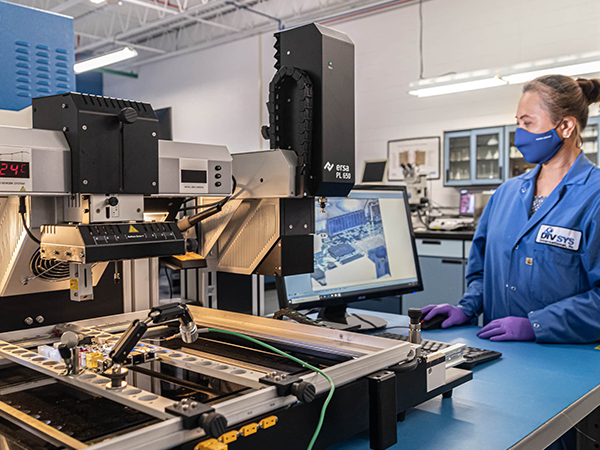

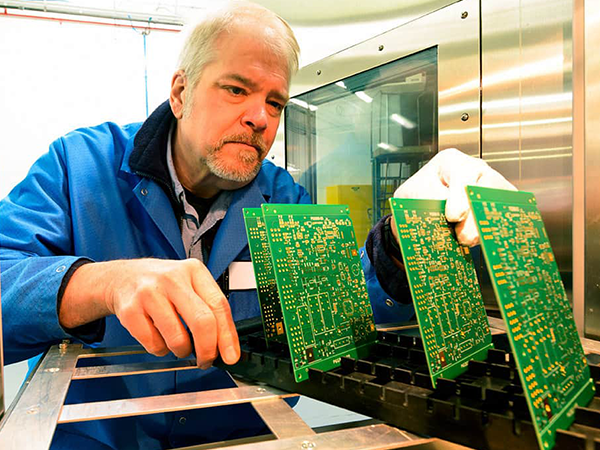

Our in-house testing lab ensures that every PCB undergoes a rigorous inspection process, guaranteeing it is approved for use.

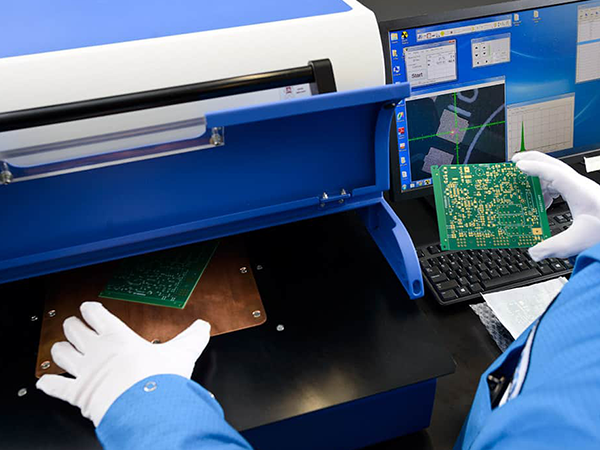

Advanced X-ray inspection ensures the integrity of hidden solder joints, such as BGA (Ball Grid Array) connections, detecting defects that are not visible through traditional inspection methods.

This advanced technique involves mounting components directly onto the surface (top or bottom) of the PCB, allowing for efficient and compact assembly.

Comprehensive end-to-end PCBA assembly solutions, including integration of components, wiring, enclosures, and final testing, delivering fully functional, ready-to-use electronic products.

Comprehensive PCBA testing solutions, including functional testing, in-circuit testing (ICT), and custom test fixture development, ensuring product reliability and quality assurance.

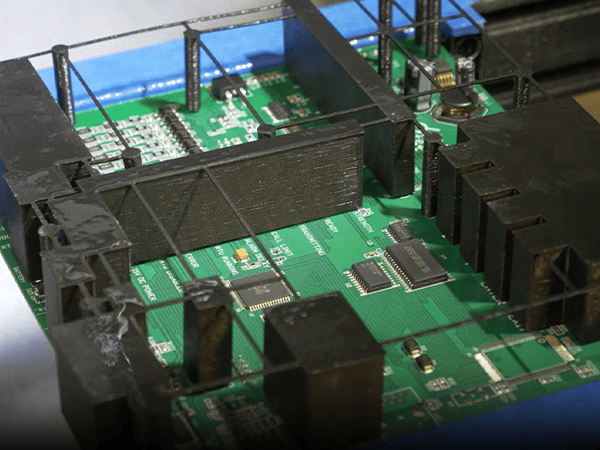

A thin protective layer is applied to the PCB to shield it from moisture, dust, chemicals, and extreme temperatures, enhancing durability.

A manual or automated process used to desolder and re-solder components, correcting design issues or production defects.

A thorough quality control process where PCBAs are examined under microscopes to identify and prevent potential failures.

This step involves separating individual PCBAs from a larger panel or array, preparing them for final testing and assembly.

A critical post-production cleaning process that removes flux residues and other contaminants, ensuring high-quality and reliable circuit boards.

In this method, component leads are inserted into drilled holes on the PCB and then soldered, ensuring secure electrical connections.